R&D Capability

Design

Design

Design

Design

Design

Testing

Professional technology solution

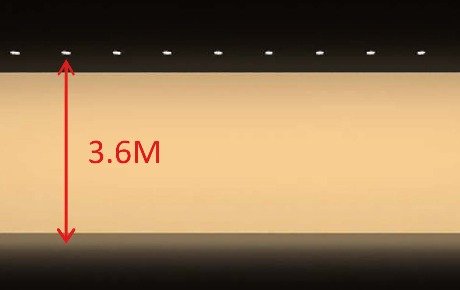

Perfect Wall Washer Effect

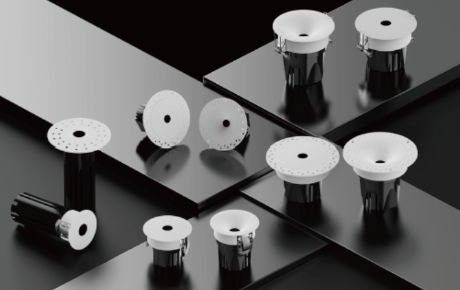

Tiny light emmitting technology

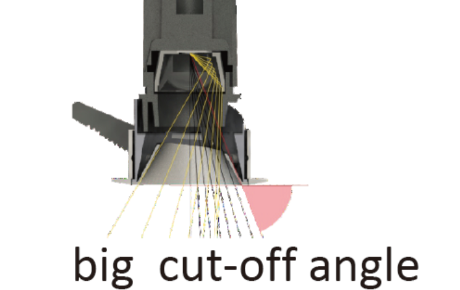

Anti-glare mechnical design

Precise beam angle control

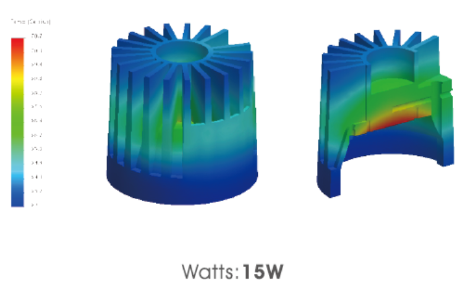

Heat dissipation simulation

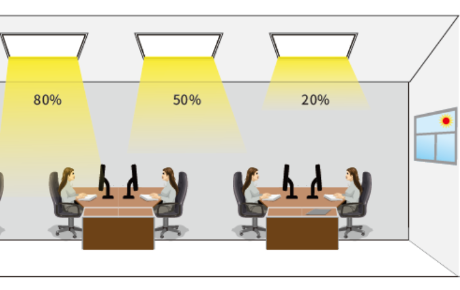

Daylight sensing technology

Top chipset partner, precise light color control

What is Personalized Lighting

Choices: lighting that changes as you do. As you work, as you play, as you create, as you live. AMAZ has embraced technology advancements and change by creating lighting products that support what you do. Choose the AMAZ Light color technology that’s right for you

Dim to warm Technology

Manufacturing Strength

CNC Machine

Die casting

Aluminum bending Machine

SMT machine

Cold forged machine

Powder Coating

Reliable and High-Quality Supply Chain

Quality Control

SDCM <3 L80(B10)@50,000H

to choose perfect light spot

Roundness Tolerance ±0.3 mm

Perfect powder painting, color aberration <0.7

Assembling Gap/ Step Drop <0.3mm

Safety package & delivery

Whole Process Quality Control

Incoming Material Quality IQC

Input Process Quality Control IPQC

Finished Products Inspection FQC

Pre-shipment Aging Test

Enviromental Packaging

Outgoing Quality Control OQC

Safe Delivery

Strict Tracking System

sales@amazlight.com

sales@amazlight.com